Category

Full Automatic Digital Cutter for Corrugate Packaging

Overview Full Automatic Digital Cutter For Corrugate Packaging Model: CB03II-2513-RM, CB03II-2516-RM Specifications Core

Basic Info

| Model NO. | CB03II Series |

| Automatic Grade | Automatic |

| Application | Paper Packaging Materials, Stickers Products |

| Moving Speed | up to 1500mm/S |

| Cutting Speed | up to 1200mm/S(Depend on The Kinds of Material) |

| Repeatability | +/-0.05mm |

| Safety Device | Infrared Sensor, Responsive, Safe and Reliable |

| Cutting Material Affixed | Smart(Optional) Individual Multi-Zone Vacuum Sucti |

| Interface | Ethernet Port |

| Numerical Control Panel | Multi-Language LCD Touch Scream |

| Transport Package | Standard Exporting Package: Polywood Carton |

| Specification | 3650mm*2320mm*1280mm; 3650mm*2620mm*1280mm |

| Trademark | EcooGraphix |

| Origin | China |

| HS Code | 844110 |

| Production Capacity | 1000 Sets Per Year |

Product Description

Full Automatic Digital Cutter For Corrugate Packaging

Specifications

| Model | CB03II-2513-RM | CB03II-2516-RM |

| Multiple function machine head | Easy to change different tools. Engraving and routers. Oscillating through cutting/kiss cutting/ceasing/plotting/laser positioning and precise camera registration. | |

| Tools | Various kinds of cutting blades, different size of creasing wheels. | |

| Safety device | Infrared sensor, responsive, safe and reliable | |

| Moving speed | Up to 1500mm/s | |

| Cutting speed | Up to 1200mm/s(depend on the kinds of material) | |

| Cutting thickness | ≤50mm(customized according to different materials) | |

| Cutting material | All kinds of corrugated paperboard, grey board, KT board, PVC expansion sheet, honey comb board, car sticker, light slide, PP gum, flex banner, flag fabric, EPE foams, EVA, PVC plate, acrylic, thick foam, etc | |

| Cutting material affixed | Smart (optional) individual multi-zone vacuum suction | |

| Repeatability | ±0.05mm | |

| Interface | Ethernet port | |

| Numerical control panel | Multi-language LCD Touch Scream | |

| Transmission | Imported (digital servo motors, straight rail, synchronous belt, guide screw) | |

| Related powder | 9.5 kw | 9.5 kw |

| Related voltage | 380V/220V±10%, 50hz/60hz | |

| Max. cutting size | 2500mmx1300mm | 2500mmx1600mm |

| Machine size | 3650mmx2320mmx1280mm | 3650mmx2620mmx1280mm |

Core Technology

1. High end 6-axis speed motion control system.2. Conveying flatbed design, with optional automatic board loading system, achieves automatic production of rolls and board material, shortening tack time and improving efficiency.3. Integrater software control of high performance.4. Digital fine tuning for kiss-cut and thorough cut, dotted line and creasing.5. New intelligent sub-area vacuum suction with high suction force. (small cutting material appressed closely and firmly to the mat easily)6. High standard design for long time batch production.Features And Strength

1. Perfect for small order of package or label, especially for sample order.2. Save the cost of cutting die, flexible and affordable.3. Covering all kinds of packaging material, with multiple optional affix to extend its function.| Standard Tools: | ||

| Electric oscillating tool (EOT) | ||

| Universal cutting tool (UCT) | ||

| Multi-angle V-cut tool for grey board | ||

| Creasing wheel tool | ||

| Optional Tools: | ||

| Multi-angle V-cut tool for grey board, flexo plate | ||

| V-cut tool for photo frame, flexo plate | ||

| V-cut tool for cardboard | ||

| Perforation wheel tool (E-flute, 3mm hole, 2mm gap) | ||

| Conveyor belt system | ||

| Foam cutting tool | ||

| CCD camera registration system | ||

| Automatic sheet feeding device (1.6m width) |

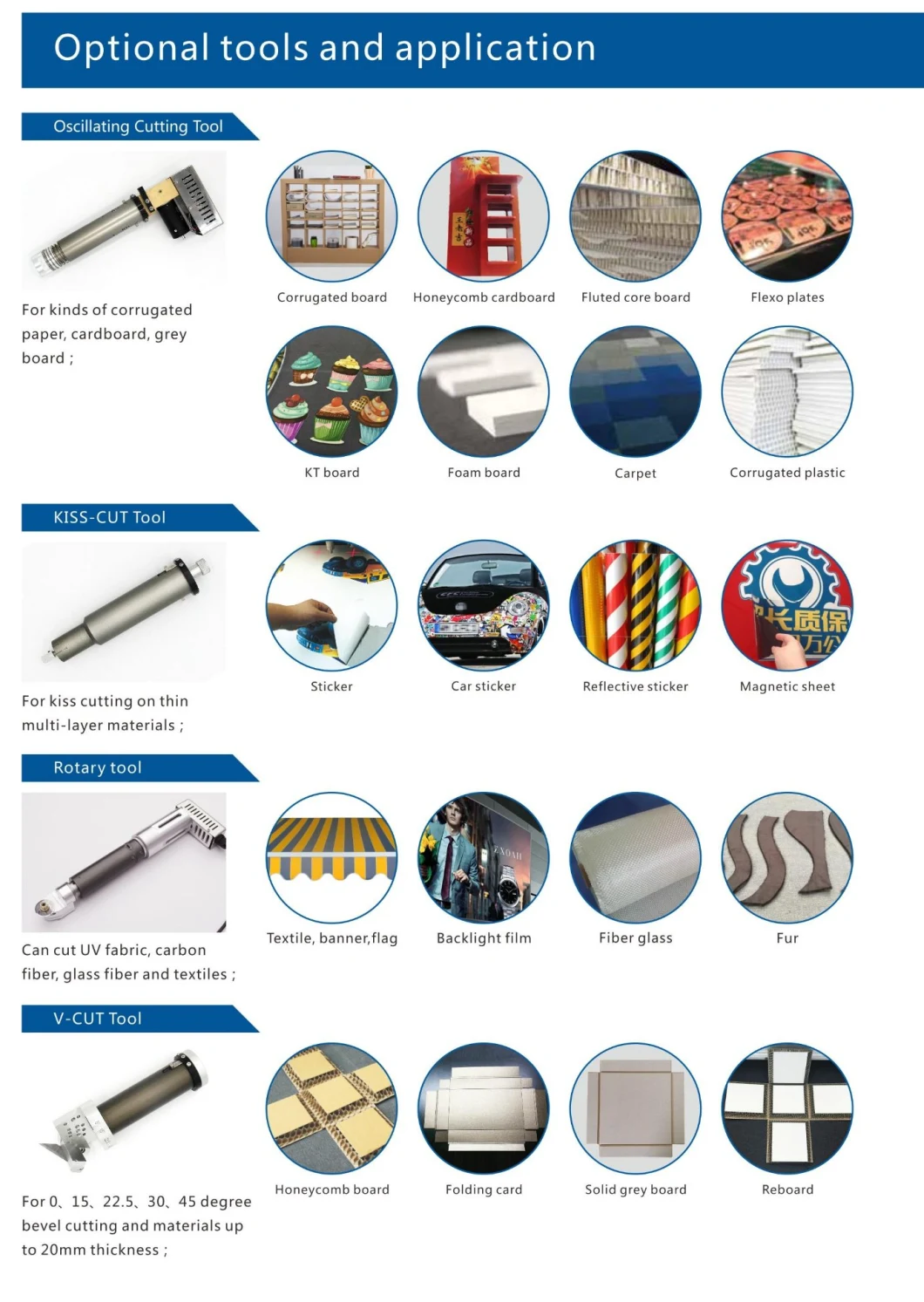

Tools And Application

Producing and Packaging

From producing to delivery, we make every details very carefully to guarantee the good product quality and service to customers.

Certifications

FAQ

Q1: What are your main products ? A: Our main products are the Prepress 4up and 8up Online/Offline Thermal CTP, CTCP, VLF CTP, Flexo CTP, Processor, Offset Plates, Offset Inks, Offset Printing Blankets, Postpress Packing Equipment and so on.You can get the equipment and consumables all in one and no worry about the after-sales service from our company. |

Q2: Where is your factory ? A: Our CTP Processor machine factory is in Shanghai, you are warmly welcome to visit our factory! |

Q3: What is your warranty for the CTPs ? A: Three years' Laser Head and main spare parts for the CTPs, one year for the Processor.If the customer uses Ecoographix CTP plate with the CTP machine, we will provide the Lifetime Warranty. |

Q4: Can you also supply the Workflow and RIP ? A: Yes, we can provide the Workflow Brainnew and RIP Compose V12. |

Q5: What about the installation and after-sales technician support ? A: Our engineer can go to help the installation and provide the necessary training. The buyer should take the round air plane tickets and service charge and the local accommodation cost. Any problems or questions, we will be at your disposal 7x24 hours. Among our large amount of CTP installations worldwide, there are also many end users (printers) who have purchased the CTP products from EcooGraphix China directly and EcooGraphix technical service team support these installations remotely with regular onsite visits.These end users Printers all run the CTP systems with full satisfaction due to our robust quality, seamless remote service, thorough training and maintanence. If you are a printer who is considering purchasing directly from EcooGraphix China, there is no hassle on installations, training and after sales service. We guarantee your satisfaction. |