Category

Hydroxypropyl Methyl Cellulose HPMC Hypromellose Cellulose Ether for Water Based Paints

Hydroxypropyl Methyl Cellulose (HPMC) SidleyCel® Hydroxypropyl Methyl Cellulose (HPMC) is non-ionic cellulose ether made

Basic Info

| Color | White |

| Appearance | Powder |

| Transport Package | 25kgs/Bag |

| Specification | 25kg/bag |

| Trademark | SidleyCel |

| Origin | China |

| HS Code | 39123900 |

| Production Capacity | 3000mts Per Month |

Product Description

Hydroxypropyl Methyl Cellulose (HPMC)SidleyCel® Hydroxypropyl Methyl Cellulose (HPMC) is non-ionic cellulose ether made from natural cotton fiber under series of chemical processing. It's odorless, tasteless and non-toxic white powder, can be dissolved in cold water to form a transparent viscous solution with the properties of thickening, binding, dispersing, emulsifying, film coating, suspending, absorbing, gelling, water retention and colloid protection.

| Product Name | Hydroxypropyl Methyl Cellulose (HPMC) |

| HS CODE | 39123900 |

| Function | Thickening agent, water retention agent |

Dishwash liquid, detergent as thickener with good transparency high viscosity

PVC suspension polymerization in the polymerization system as dispersant to imporove the suspension and dispersion

Tile Adhesive

- Using HPMC, tile adhesive will easy to mix with water without lump appeared and saving time. Due to the more rapid and efficient operation, we can improve the workability and reduce the cost.

- The water-retaining property of MHEC extend the drying time of mortar, so as to improve the efficient of fixing.

- HPMC provide good bonding effect with highly skid resistance.

- HPMC can improve the uniformity of plastering mortar, making it easy to coating, at the same time improve the ability of anti-sag. It can also boost liquidity and pumpability of mortar, to improve the work efficiency.

- With high water retention, MHEC can prolong the working time of mortar, improve work efficiency, and help the mortar obtaining high mechanical strength in solidification period.

- HPMC can control air infiltration, to eliminate the tiny cracks of coating, to format the ideal smooth surface.

- HPMC can improve the adhesiveness between mortar and masonry. And the water-retaining property of MHEC is useful in raising the strength of mortar.

- HPMC improves the lubricity and plasticity of mortar, so as to make the construction easier, to save time, to reduce the cost.

- For superabsorbent masonry, it is more important to use MHEC in the mortar.

- Excellent water retention of HPMCcan prolong drying time of crack filler, it is helpful to improve work efficiency. Also, the high lubricity makes construction easier and more smooth.

- HPMC can improve the shrinkage resistance and crack resistance of crack filler, to perfect the surface quality.

- HPMC makes the construction surface fine and smooth. Meanwhile, the adhesiveness get improved.

- HPMCcan improve the uniformity of plastering mortar, making it easy to coating, at the same time improve the ability of anti-sag. It can also boost liquidity and pumpability of mortar, to improve the work efficiency.

- With high water retention, HPMC can prolong the working time of mortar, improve work efficiency, and help the mortar in obtaining high mechanical strength in solidification period.

- HPMC can keep the consistency unified, forming a good surface.

- The viscosity of HPMC has the effect of anti precipitation.

- HPMC can enhance the product liquidity and pumpability, so as to improve the efficiency of the flooring.

- The water-retaining property of HPMC can avoid excess air infiltration. Therefore, crack and contraction are greatly reduced.

- The suspension property of HPMC can prolong expiration date by prevent solid precipitation. Meanwhile, it has good compatibility with other ingredients and biological stability.

- HPMC helps the product dissolving rapidly without lump.

- HPMC makes coating has good flow property and low splash, resulting a fine and smooth surface.

- HPMC can increase the viscosity of the paint remover, make it not out of work scope

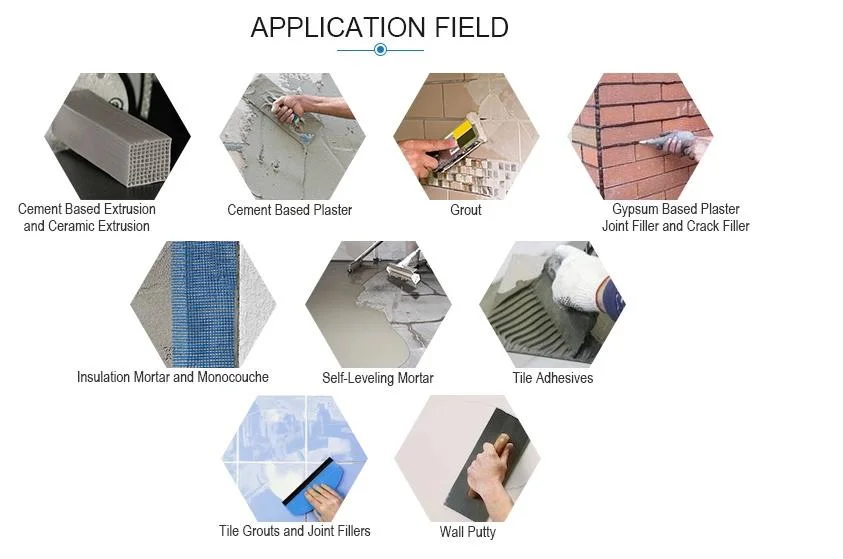

Sidley Cehmical was established in 2005 and specialized in cellulose ether production, sales and export trade as one of the manufacturer. As one of the world top-level supplier for cellulose ether, our products can be widely used in

Food,Pharmaceuticals industry, Paints & Coating, Construction, Ceramics, Oil drilling, Paper making and Printing Industry and Detergent etc.

Under mature manufacturing technique, Sidley Chemical controls the cost effectively and possess more excellent competitive products.We make great efforts to research new products in order to make the products widely used and supply the technology service for all customers.

Our Exhibitions

Our Plant

Our Laboratory and equipments

Contact us

Linda Wang

Linyi City, Shandong Province,China

Drymix Mortar Additives Supplier and Technical Support

Cellulose Ether Supplier