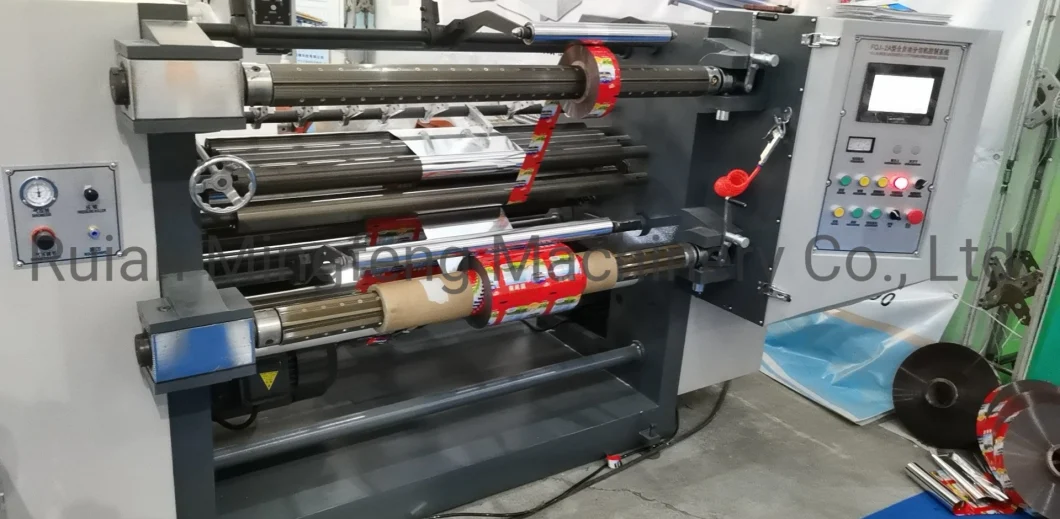

Quality High Speed Jumbo Roll Cutting Machine Paper Slitting Rewinder Price

Basic Info

| Model NO. | LFQ1100/1300/1600 |

| After-sales Service | 24 Hours on Line |

| Warranty | One Year |

| Application | Mechinery&Hardware |

| Type | High-Speed Slitting Machine |

| Work Method | Round Knife Cutting |

| Structure | Guide Roller Part |

| Packaging | Film |

| Classification | Ultrasonic Label Cutting Machine |

| Applicable Process | Process Materials |

| Suitable Substrates | Film Cutting |

| Packaging Material | Plastic |

| Max. Slitting Speed | 200m/Min |

| Max. Unwinding Dia | 600mm |

| Max. Rewinding Dia | 400mm |

| Max. Unwinding Width | 1600mm |

| Total Power | 6kw |

| Weight | 1700kg |

| Certifications | CE,SGS |

| Transport Package | Nude Packing |

| Specification | 2950*1400*1300mm |

| Trademark | MINGFENG |

| Origin | China |

| HS Code | 8515809000 |

| Production Capacity | 50sets/Year |

Product Description

Quality High Speed Jumbo Roll Cutting Machine Paper Slitting Rewinder PriceProduct Description

2. touch screen man-machine interface operation, concentrated display and control working state, speed, tension and other parameters.

3. The design of one button to Start/Stop realizes linkage control of tension switch, main motor start/stop and others; before start the machine, only need to input some simple parameters, such as the thickness and the diameter of raw materials, speed, etc., all the work done by the computer automatic calculation.

PLC can realize the functions of meter counting while rewinding, presetting meters for auto stop, and auto stop while unwinding roll is end.

4. Main motor adopts frequency speed adjustment

5. horizontal structure, with unwinder and rewinder at the different side.

6. Cast iron body, guarantee the stability at high speed.

7. Air-expansion shaft for unwinding, the full shaft can be disassembled and has one end rotatable. Double-photoelectric computer E.P.C system is installed at first unwinding

8. Both up rewinding and down rewinding adopt air-expansion shafts, with pressing rollers. The rewinding shafts have one end rotatable, convenient for unloading, with heavy type rotating structure(not universal joint) that is durable. The shafts are locked by pneumatic.

9. Rewinding adopts high brand outward turning magnetic powder clutch with fast cooling. Magnetic powder clutch is transmitted by synchronous belt

10. Slitting edge is blown out by high power blower through recycling pipe at the right side of the machine.

11. All guide rollers are highly hardened aluminum alloys, with static and dynamic equilibrium treatment.

Main Technical Parameters:

Model | LFQ1100/LFQ1300/LFQ1600 |

Max. slitting speed | 200m/min |

Max. unwinding DIA | 600mm |

Max. rewinding DIA | 400mm |

Max. unwinding width | 1100mm/1300mm/1600mm |

Total power | 4.8kw/5kw/6kw |

Weight | 1500kg/1600kg/1700kg |

Dimension | 2450*1400*1300mm/2650*1400*1300mm 2950*1400*1300mm |

Machine Details

Our Workshop

Company Profile

Packaging & Shipping

Certifications

After Sales Service

100% Good Machine QualityOne year Guaranty Time 24 hours On Line Service Overseas Technician AvailableCotact Girl:Ms.Amy Warmly welcome you to contact us freely !FAQ

1

Q:Are you machinery factory or trading companyA:We are machinery factory,and also have one trading company2

Q:Where is your factory located?

A:We are located Ruian City,Zhejiang Province,ChinaFrom SHANGHAI by air is 40 mins,by train is 4 hours.From GUANGZHOU by air is 2 hours.3

Q:How many years warranty?Can you teach us?

A:Usually,we given customer one year warranty time.We also have oversea technician service to help you install the machines.4

Q:What's the payment method?

A:We can accepted T/T,L/C,Western Union,Moneygram and etc.