Category

Wood Die Cutting Laser Cut Machine

Polywood Die Board Laser Cutting Machine & Auto Bender Machine For Die Cutting 1,400W can be a single head laser cutting

Basic Info

| Model NO. | wt-lc400 |

| Structure Type | Gantry Type |

| Laser Classification | CO2 |

| Laser Technology | Laser Control Fault Cutting |

| Cutting Speed | 8-12 mm/S |

| CNC or Not | Yes |

| Graphic Format Supported | Ai, BMP, Dxf, Dxp, Plt, ... |

| Cutting Area | 1200*1800mm |

| Usage | Laser Die Board Laser Cutting |

| Name | Gy Laser Cutting Machine |

| After Sale | Engineers Available to Service Over Seas |

| Laser Type | Sealed CO2 Laser Tube |

| Certification | CE TUV |

| Control Software | Wt Laser Cutting Machine Software |

| Cutting Precision | 0.01mm |

| Cutting Gap | 0.45 0.71 1.05 1.07 1.42mm |

| Cutting Thickness | 8-30mm |

| Motor | Servo Motor |

| Transmition | Hiwin Screw Linear Guider |

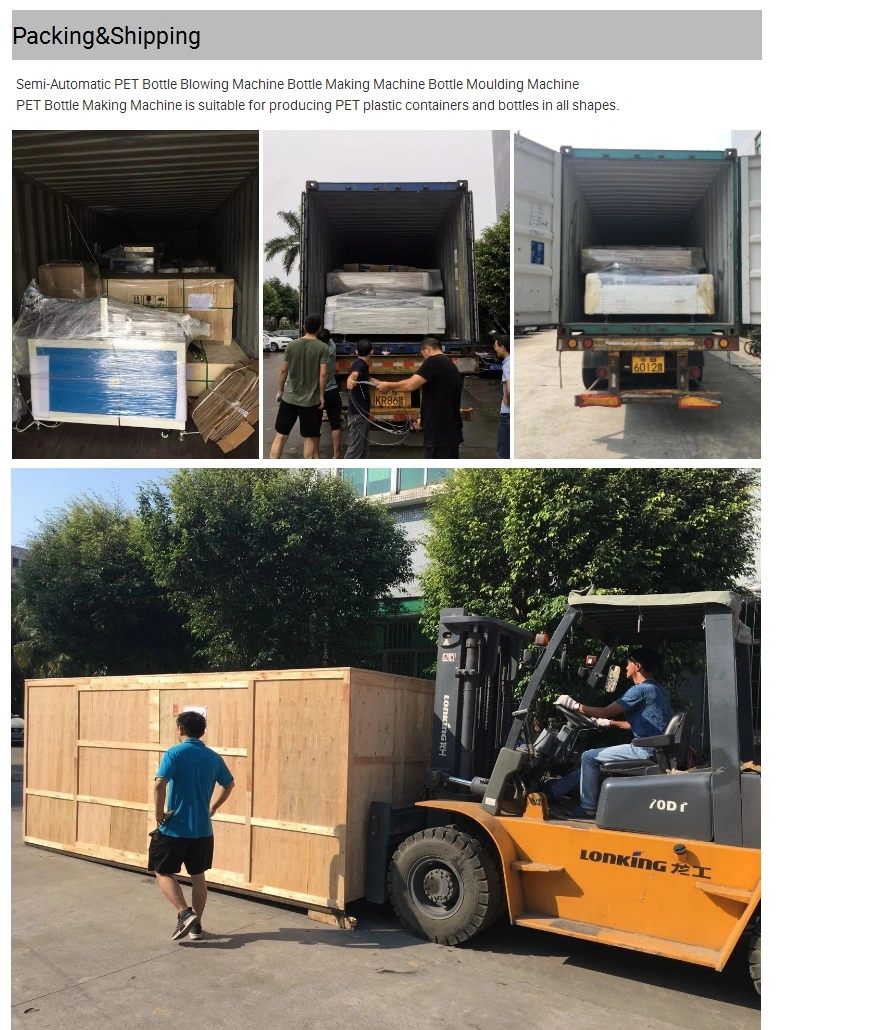

| Transport Package | Export Standard Wooden Case |

| Specification | 3400*2300*1200 |

| Trademark | WT |

| Origin | Dongguan City China Prc |

| HS Code | 8456110090 |

| Production Capacity | 1000PCS/Year |

Product Description

Polywood Die Board Laser Cutting Machine & Auto Bender Machine For Die Cutting1,400W can be a single head laser cutting die cutting machine cutting 18mm and 22mm board laser cutter template,6-9mm PVC rubber sheet(add oxygen can cut iron plate ,stainless steel,13mm can do blister knife template ,high efficiency ,uniform kerf ,consistent ,the precision error is less than 0.1mm. Maintenance is simple. Do not need gas. Equipment structure is compact .Need small area to install it. The cabinets are made of high quality cold-rolled steel plate,An external power source 220V. and low cost. Technology of simple knife adjustment ,cutting software and AutoCAD ,CorelDraw, Adobe Photoshop can compatible edit the path manual operation. maintenance cost is low. greatly saves the production cost of laser cutting die.

2,Adopt the most advanced 400W C02 sealing type water-cooled laser tube combined with precision up to 0.05mm of numerical control mechanical systems. Not only Get The precision of laser die making, But also reduce the costs of laser die making. Suitable for wooden board laser die cutting and precision electronic laser die making. Adopt gantry structure ,to avoid the optical path deviation size problem that high power laser machine has.

3,Do not need to add any auxiliary gas to cut, laser cutting die consumption is extremely low. an external power source 220V is ok. And no opening preparation delay. The cutting costs is only 5 RMB/Hour

4,Can do one-time cutting 1mm-22mm wooden board, Plastic board, organic glass, Acrylic board at speed of 25-30m/h. And the machine can cut the gap at 0.45mm, 0.71mm, 1.07mm, 1.42mm and so on at uniform cutting kerf width also up and down seam.

| Technical Parameters | |||

Transmition | High Precision HIWIN Screw guide | ||

| Laser Type | CO2 direct-current stimulated glass laser | ||

| Server Motor | Inovance high precision server motor | ||

| Re-positioning Precision | +-0.02mm | ||

| Cutting Precision | +-0.01mm | ||

| Cutting Board Thickness | 1-25mm poly wood (Cut 1.5mm stainless steel board and 3mm Normal steel when Add oxygen gas) | ||

| Cutting Speed | 1-35m/h (18mm wooden board) 1-30m/h(18mm wooden board) | ||

| Pneumatic parts: | Taiwan-- AirTag | ||

| Best Files format | DXF,DWG,AL,CDR,PLT (Auto Cad, Core Draw) | ||

| Cutting Size | X-axis travel length: 1200mm Y-axis travel length : 1800mm | ||

| Power | 4kw 220V/ 60HZ 50HZ | ||

| Laser Power | 400W Single Header | ||

| Work Temperature | 0-45ºC | ||

| light-dimmer | 1 Pcs | ||

| Tool | 1 Sets of tool box | ||

| Focus Len | 1 Pcs of | ||

| Laser Tube | 1 Pcs of QT 400W laser tube | ||

| high efficiency air filter | 1 Sets | ||

| Smock Exhaust fan | 1 Pcs | ||

| Water Cooling | CW-6000 | ||

| Warranty | 12 month (except laser tube and lens) | ||

| Weight | 2000kg | Overall Size | 3400*2300*1500 |

Machine Details:

>>> Please Let Us Know

1.what machine do you need?2.what materials will be processed? The size and thickness?3.what is your business scope? Are you end user or distributor?

Any more product information, please contact us ! Customer Needs is my Pursuit !